Inventory Management

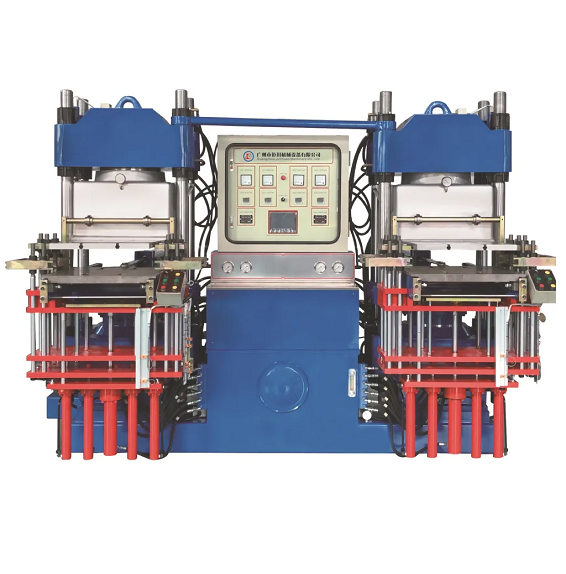

Machinery

Our vast infrastructure enables us in attaining our predetermined goal of fabricating excellent quality range of Rubber Products. This facility is divided into various functional units such as manufacturing unit, quality testing, administrative and warehousing unit & is well-equipped with advance machinery and equipment.

Further, our state-of-the-art infrastructural unit is completely incorporated as per the set industry norms. These units help us deliver products as per the specific requirements of clients in timely manner. To keep this abreast with technological changes, we upgrade our infrastructure on various time intervals. In order to get the full satisfaction of our clients, we also take bulk orders of our clients.

Powder coating

Powder coating is a finishing process used to apply a durable and attractive coating to metal surfaces. The result is a uniform, resilient finish with advantages such as durability, environmental friendliness, and a wide range of color and texture options.

Finishing

We boast a dedicated finishing area, which consist of only women. Promoting women empowerment in our business is not just a moral duty but a strategic advantage. Fostering an inclusive environment drives innovation and diverse perspectives.Our commitment involves equal opportunities, fair compensation, and a supportive culture for women to thrive. By breaking down barriers, we unlock untapped potential, enriching individual lives and strengthening our organization collectively. Together, we build a workplace where everyone, regardless of gender, can succeed and contribute meaningfully to our shared success.

Tool Storage

In our rubber molding company, the mold storage system is meticulously organized to enhance efficiency and ensure the longevity of our molds. We categorize molds based on type, size, and usage, employing sturdy shelving and racks for systematic storage. Security measures and inventory management system are in place, allowing for easy tracking and safeguarding against unauthorized access. Regular inspections, well-documented maintenance records, and established safety protocols contribute to the overall maintenance of the molds. Additionally, we prioritize space optimization and plan for future mold additions to accommodate the company’s growth.